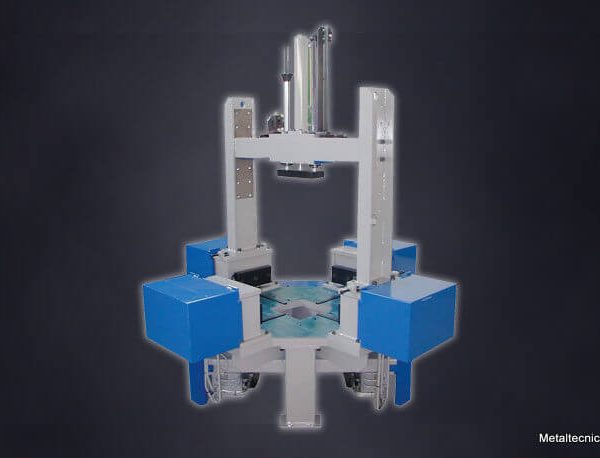

BO-ROTATING 5 casting machine, suitable for the production of gravity casting parts of non-ferrous alloys, specifically aluminum parts. Composed of: fixed base, 0-180 ° rotating table, 2 tilting head-holder benches, 1 movable head n ° 1 fixed head per pallet, mold holder tables with 0-180 ° rotation with proportional logic, heads with 0-90 rotation for mold cooling / stapling, mold cooling / stapling tank complete with agitators and internal cooling coil, upper horizontal and vertical male insertion carriage, electrical management system, hydraulic control unit. Use in work cell with interlocking with anthropomorphic casting robot.

Additional information

| Rotation | 0-180° |

|---|---|

| Single head capacity | 100 Kg |

| Rotating | D 560 mm |

| Max opening between heads | 900 mm |

| Moving head stroke | 500 mm |

| Tables connections | customizable |

| Tables dimensions | customizable |

| Tables stroke | customizable |